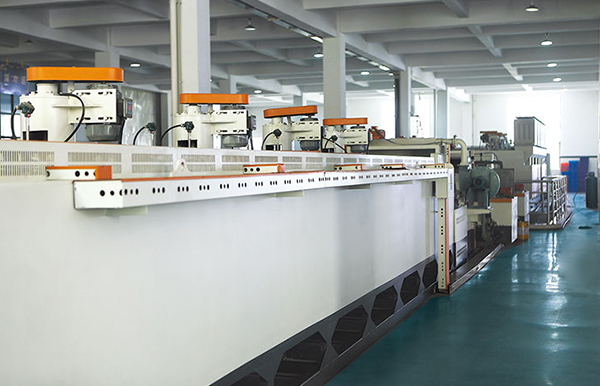

Production Equipment

AVIC has sophisticated intelligent manufacturing equipment

The company vigorously introduces various types of equipment in the leading industry, from high-speed upsetting of bearing steel, automatic high-precision turning and milling, cryogenic quenching, unitized automatic constant temperature grinding, and the formation of a complete industrial chain of intelligent assembly will provide AVIC The core hardware data processing of the bearing has achieved a stable and reliable foundation. It has nearly 1,000 sets (sets) of bearing production and testing equipment. Advanced finishing equipment includes: double end grinder, CNC raceway grinder, data internal grinder, automatic bearing assembly production line, tapered roller automated production line, etc., demanding fiber and nanometer, forging extremely sophisticated bearing products; testing equipment includes: surface Profilometers, metallographic microscopes, surface roughness meters, roundness meters, projectors, projection universal length measuring instruments, bearing vibration measuring instruments, strictly adhere to the original intention of quality, and create first-class quality that can withstand the test of market and time. Product presentation:Deep groove ball bearings , Insert bearings(Y-bearings) , Angular contact ball bearings , Self-aligning ball bearings , Thrust ball bearings , Cylindrical roller bearings , Needle roller bearings ,Tapered roller bearings ,Spherical roller bearings ,CARB toroidal roller bearings , Cylindrical roller thrust bearings , Needle roller thrust bearings ,Spherical roller thrust bearings , Cam rollers , Support rollers , Cam followers ,pherical